Secret Benefits of Making Use Of Metal Spreadings Across Numerous Fields

Metal spreadings act as an essential component in different markets, supplying distinct advantages that boost efficiency and efficiency. Their style flexibility allows for detailed shapes, while their product properties add to total toughness. Cost-effectiveness and sustainability more underscore their significance in modern manufacturing. As sectors remain to advance, recognizing the complete range of benefits offered by steel spreadings comes to be vital for tactical decision-making. What effects do these benefits hold for future technologies?

Boosted Layout Versatility

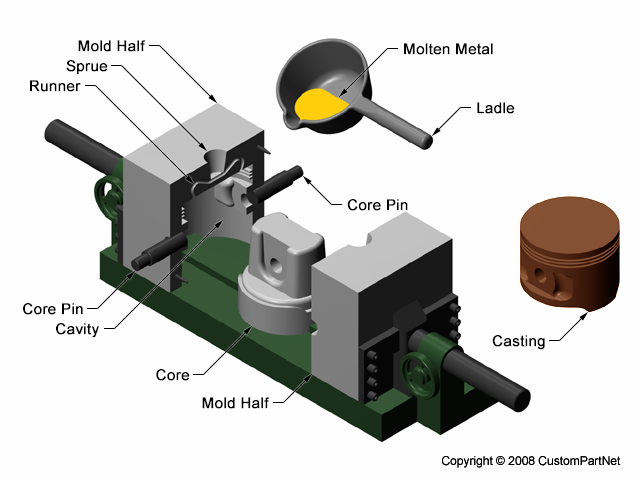

Although traditional production methods frequently impose constraints on layout complexity, metal spreadings provide remarkable adaptability that enables elaborate shapes and attributes. This flexibility enables developers to create parts that would be difficult or tough to attain with other methods. The spreading procedure, which includes pouring molten metal right into mold and mildews, can accommodate a selection of geometries, making it ideal for varied applications varying from automotive to aerospace.

The capacity to produce both small and big components with in-depth styles boosts the total functionality of the items. Developers can enhance weight and efficiency by integrating complicated inner structures, such as cooling down channels or support ribs (Aluminum Foundry). In addition, steel castings can facilitate the incorporation of numerous attributes right into a single part, reducing the demand for setting up and reducing possible points of failing. The enhanced layout adaptability of metal castings not just promotes advancement yet also contributes significantly to performance in manufacturing processes.

Improved Product Qualities

When thinking about the advantages of steel castings, among the most substantial advantages exists in their enhanced product buildings. Metal spreadings typically show boosted toughness and durability contrasted to various other making methods. This raised resilience is attributed to the controlled cooling process during casting, which enables a consistent microstructure. Because of this, cast steels can stand up to higher degrees of anxiety and exhaustion, making them excellent for demanding applications.

Metal castings use exceptional corrosion resistance, especially when alloys are used to improve efficiency in rough atmospheres. This particular extends the lifespan of components and minimizes the requirement for frequent replacements. Additionally, the ability to create complicated forms without compromising structural stability better boosts the functionality of cast parts. As a result, markets varying from vehicle to aerospace gain from the durable and reliable nature of steel spreadings, ensuring peak efficiency and safety in their applications.

Cost-Effectiveness and Lowered Waste

Steel spreadings present a considerable advantage pertaining to cost-effectiveness and decreased waste, complementing their enhanced material properties. Traditional production methods usually need considerable machining and finishing processes, which can generate significant scrap material and sustain high labor expenses. In contrast, metal casting enables for the production of complex shapes in a single procedure, reducing the requirement for additional processing and reducing material waste.

Additionally, metal casting makes use of molds that can be recycled several times, further decreasing production prices gradually. The capacity to cast complex designs likewise implies that manufacturers can achieve greater style adaptability without jeopardizing on quality, therefore preventing expensive redesigns. In general, the cost-effectiveness of steel spreadings not just advantages makers by reducing expenditures however likewise sustains sustainability initiatives by minimizing waste. This dual advantage makes metal castings a recommended selection throughout different sectors, consisting of automotive, aerospace, and building and construction

Boosted Production Effectiveness

Raised manufacturing efficiency is a substantial advantage of metal spreadings, as it promotes streamlined manufacturing processes. By maximizing these procedures, firms can successfully minimize product waste and accomplish faster turn-around times. This combination not just improves efficiency but also adds to overall functional excellence.

Structured Production Processes

As making needs progress, the fostering of structured processes comes to be important for enhancing manufacturing performance. Steel castings play a crucial duty in accomplishing this goal by facilitating much faster manufacturing cycles and minimizing lead times. Their inherent style flexibility enables manufacturers to create intricate forms with minimal setting up requirements, consequently streamlining workflows. Advanced spreading strategies, such as precision spreading and 3D printing, add to higher precision and uniformity, additional optimizing procedures. By integrating steel spreadings right into making processes, firms can accomplish higher automation, which decreases hands-on intervention and speeds up throughput. Streamlined procedures not only boost performance but also enable manufacturers to react quickly to market changes, making certain competitiveness in an increasingly vibrant landscape.

Decreased Material Waste

Lowering material waste is a crucial advantage of using steel spreadings in manufacturing. This procedure permits near-net-shape manufacturing, where elements are developed with minimal excess product. By utilizing steel casting strategies, suppliers can substantially decrease the amount of scrap produced compared to typical machining methods. This reduction in waste not only preserves raw materials yet additionally reduces expenses linked with product procurement and disposal. Furthermore, less waste adds to extra lasting production techniques, straightening with environmental goals. The effectiveness achieved via steel spreadings improves general production processes, allowing firms to maximize source usage while preserving quality requirements. This critical technique ultimately brings about boosted financial efficiency and a decreased environmental impact, benefiting both producers and society at large.

Faster Turnaround Times

Faster turnaround times stand for a remarkable benefit in the domain of metal castings, enhancing overall manufacturing performance. By enhancing the spreading procedure, producers can substantially decrease lead times, enabling quicker distribution of ended up items. This performance is specifically useful in industries that demand fast feedback to market modifications, such as aerospace and vehicle markets. The ability to create components promptly not just meets customer expectations but additionally minimizes downtime in assembly line. Furthermore, developments in innovation, such as enhanced mold layout and automation, contribute to these expedited processes. Faster turnaround times in metal casting not just reinforce functional outcome yet additionally provide a competitive edge, enabling companies to respond promptly to evolving consumer demands and decreasing the threat of obsolescence.

Superior Toughness and Resilience

While various materials compete for supremacy in manufacturing, metal spreadings constantly demonstrate premium toughness and toughness, making them a perfect choice for numerous applications. The inherent homes of steels, such as their high tensile strength and resistance to use, ensure that castings can endure intense operational conditions without failing. This durability equates into longer service lives for components, reducing the frequency of substitutes and upkeep.

The capacity to develop complicated geometries with metal spreadings makes it possible for suppliers to create parts that optimize stamina without adding unneeded weight. This is especially beneficial in markets that focus on performance and efficiency, such as aerospace and automobile. Furthermore, steel castings show superb resistance to harsh atmospheres and extreme temperature levels, improving their applicability in challenging setups. On the whole, the exceptional toughness and resilience of steel spreadings position them as a foundational product in design, adding to the reliability and durability of various items and systems.

Convenience Throughout Industries

The intrinsic stamina and toughness of steel spreadings make them a functional selection throughout a wide range of industries. From auto production, where precision-engineered parts are necessary for efficiency and safety and security, to aerospace, where light-weight yet robust parts are important for trip, steel spreadings play a significant role. In the building industry, castings are employed in building components and structural structures, making certain longevity and security. The energy market makes use of steel castings in equipment and tools, assisting in effective operations in power generation and renewable resource systems. Furthermore, the clinical field gain from personalized spreadings utilized in medical tools and devices, stressing the need for dependability. This versatility allows suppliers to meet regulative demands and distinct specs, improving item functionality and performance. In general, the flexibility of metal spreadings positions them as a very useful resource throughout various industries, driving technology and efficiency.

Contribution to Sustainable Practices

Steel spreadings play a considerable role in promoting sustainable techniques with their resource reusing effectiveness. By reducing waste generation and executing power preservation approaches, the spreading process shows a dedication to environmental duty. This technique not just benefits suppliers yet likewise contributes positively to the more comprehensive environment.

Resource Recycling Efficiency

Stressing source reusing performance, metal spreadings play a vital function in sustainable methods by minimizing waste and lowering the need for new raw products. The process of recycling metals is highly effective; it enables for the reuse of scrap materials, which can be melted down and changed right into new castings. This method not only preserves power yet additionally reduces ecological impact by reducing the requirement for mining and extraction tasks. In addition, recycled steel maintains its integral residential properties, ensuring that the top quality of spreadings stays high. This way, sectors that incorporate recycled steels contribute significantly to a circular economic climate, advertising sustainability while at the same time minimizing expenses related to basic material purchase. Wisconsin Aluminum Foundry. This effective use of sources exemplifies a dedication to environment-friendly manufacturing techniques

Reduced Waste Generation

Decreasing waste generation is an essential facet of advertising lasting techniques within the metal casting sector. By optimizing production strategies and using sophisticated innovations, producers can noticeably lessen scrap and faulty products. Strategies such as precision spreading and near-net form procedures enable for better product utilization, directly decreasing the volume of waste produced. In addition, the unification of recycled metals into the spreading process not just lowers the demand for virgin products yet likewise contributes to a circular economic situation. This strategy lines up with environmental regulations and consumer expectations for sustainable techniques. Minimized waste generation not just benefits the environment however also improves operational efficiency, inevitably leading to cost financial savings for firms in various markets leveraging steel spreadings.

Energy Preservation Approaches

Enhancing energy usage is an important element of sustainable methods in the steel casting sector. By implementing innovative modern technologies and techniques, such as regenerative furnace and energy-efficient heaters, business can substantially lower energy usage throughout manufacturing. Additionally, utilizing computer-aided layout (CAD) software home allows exact modeling, minimizing product waste and energy expenditure. Making use of scrap metal recycling even more conserves energy, as it calls for much less energy compared to generating brand-new steel. Market leaders are progressively embracing renewable resource resources, such as solar and wind power, to alleviate their carbon footprint. These energy conservation approaches not just boost operational effectiveness however likewise contribute to the total sustainability of the metal casting market, aligning with worldwide environmental objectives and lowering reliance on nonrenewable fuel sources.

Frequently Asked Inquiries

What Industries Most Frequently Use Metal Spreadings?

Industries that generally use metal spreadings include auto, aerospace, building and construction, and manufacturing. These industries rely upon steel castings for creating components that require accuracy, strength, and resilience to satisfy their operational needs and find out requirements.

How Does Metal Casting Compare to Other Manufacturing Processes?

Steel casting uses benefits such as layout adaptability and facility form formation, distinguishing it from various other producing processes. Unlike machining, it successfully produces large quantities, making it optimal for numerous markets calling for long lasting elements.

What Kinds of Metals Are Normally Used in Castings?

Common metals made use of in spreadings consist of light weight aluminum, iron, steel, and bronze. Each metal uses special homes, making them appropriate for numerous applications in sectors such as automobile, aerospace, and construction, to name a few.

Exist Any Kind Of Ecological Problems With Metal Spreading?

Ecological worries with steel casting include air and water air pollution from exhausts and waste, power intake, and resource depletion. Lasting techniques, such as recycling and making use of cleaner technologies, can minimize these adverse impacts in the sector.

Just How Can I Choose the Right Casting Technique for My Task?

To pick the ideal casting approach, one ought to think about elements such as the material type, intricacy of the design, production quantity, budget plan constraints, and desired surface area finish, guaranteeing positioning with job demands and purposes.

Steel castings provide a considerable benefit concerning cost-effectiveness and lowered waste, matching their improved material residential properties. Advanced casting strategies, such as accuracy spreading and 3D printing, contribute to greater accuracy and consistency, more optimizing operations. Reducing product waste is an important advantage of making use of steel castings in production. Highlighting resource recycling effectiveness, steel castings play an important function in sustainable techniques by reducing waste and reducing the need for brand-new raw products. Furthermore, the unification of recycled metals right into the casting process not just lowers the need for read this post here virgin materials yet likewise adds to a round economic situation.